Engineered tissues are key elements in both in vitro and in vivo applications, strongly impacting the academy, pharma and clinical sectors. Bioprinting is considered the most promising method to produce such engineered tissues. However, current bioprinting methods are severely limited by both insufficient speed and spatial resolution. Long printing times decrease cell viability, while poor spatial resolution fails to recreate the heterogeneous nature of native tissues.

BRIGHTER will create a new bioprinting technology able to produce tissue surrogates with high spatial resolution at high printing speed using an original top-down lithography approach, in contrast with current bottom-up, layer-by-layer bioprinting methods.

“BRIGHTER ultimate goal is to provide a superior alternative to state-of-the art 3D bioprinting with a radically-new bioprinting technology to boost the performance of engineered tissues and create new scientific and business opportunities”

BRIGHTER TECHNOLOGY

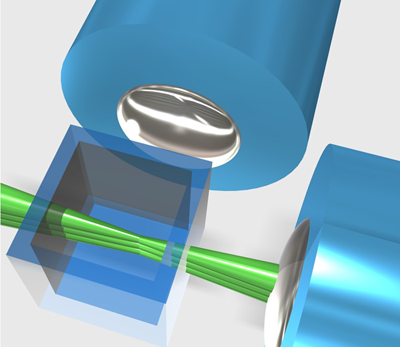

A hydrogel composed of living cells and photosensitive molecules is deposited in a special cuvette. A thin laser light sheet illuminates the gel following a programmed pattern (green beam). This leads to the formation of 3D micro-structures that reproduce the tissue architecture and function. The remaining, still liquid hydrogel is washed out after the printing process.

A hydrogel composed of living cells and photosensitive molecules is deposited in a special cuvette. A thin laser light sheet illuminates the gel following a programmed pattern (green beam). This leads to the formation of 3D micro-structures that reproduce the tissue architecture and function. The remaining, still liquid hydrogel is washed out after the printing process.

BRIGHTER will develop a new generation of bioprinting technologies able to produce tissue surrogates in an ultrafast, highly precise and cost-efficient manner. Light-sheet illumination will be used to produce the localized crosslinking of cell-laden hydrogels, creating 3D structures in a top-down lithography process.

This novel approach will make for the first-time high resolution fully compatible with high speed in a bioprinting process.

This will lead to constructs that will faithfully mimic the heterogeneous architecture, biochemical and mechanical properties of cell microenvironment within tissues without compromising cell viability due to long bioprinting periods.

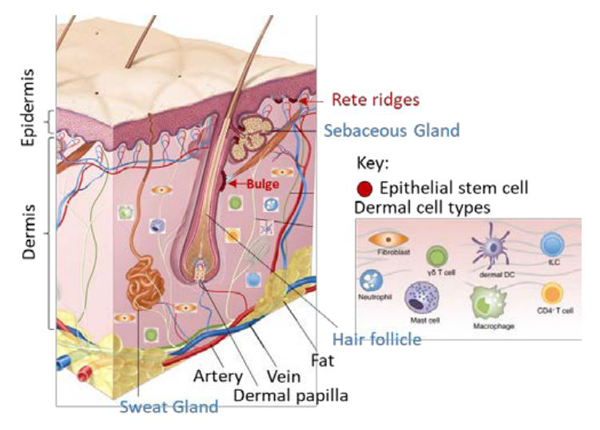

BRIGHTER technology will enable the bioprinting of key anatomical microfeatures of tissue such as invaginations, evaginations or wavy morphologies. It will also incorporate hollow vascular structures while maintaining tissue mechanical integrity without the need of additional sacrificial material. As a remarkable feature, matrix crosslinking density can be fine-tuned using BRIGHTER’s approach, allowing the fabrication of cellular compartments requiring specific matrix stiffness such as stem cell niches.

Such capabilities open new venues in the bioprinting of complex tissues with their anatomical microfeatures and incorporating specific matrix properties to compartmentalize cells and/or allow vascularization.

PROOF-OF-CONCEPT

The proof-of-concept application will be bioprinting viable engineered skin tissues exploiting the key features of the BRIGHTER device: skin appendix (hair follicles, sweat glands), stem cell niches and a vascular network. The skin is a highly dynamic, multi-layered tissue. Each layer possesses particular cell populations and ECM composition. Vascularized bioengineered skin constructs that contain not only the epidermis, but also skin appendages (hair follicles, sebaceous and sweat glands) are a huge unmet need.

The proof-of-concept application will be bioprinting viable engineered skin tissues exploiting the key features of the BRIGHTER device: skin appendix (hair follicles, sweat glands), stem cell niches and a vascular network. The skin is a highly dynamic, multi-layered tissue. Each layer possesses particular cell populations and ECM composition. Vascularized bioengineered skin constructs that contain not only the epidermis, but also skin appendages (hair follicles, sebaceous and sweat glands) are a huge unmet need.

Upcoming events:

Progress meeting 4 (M31) – Winter 2022

Scientific review 2 (M37) – Summer 2022

MAIN OBJECTIVES

-

Development of the high-resolution, high-speed bioprinting

system. - Building 3D complex structures in cell-laden hydrogels

- Proof-of-concept: engineering complex skin tissue models