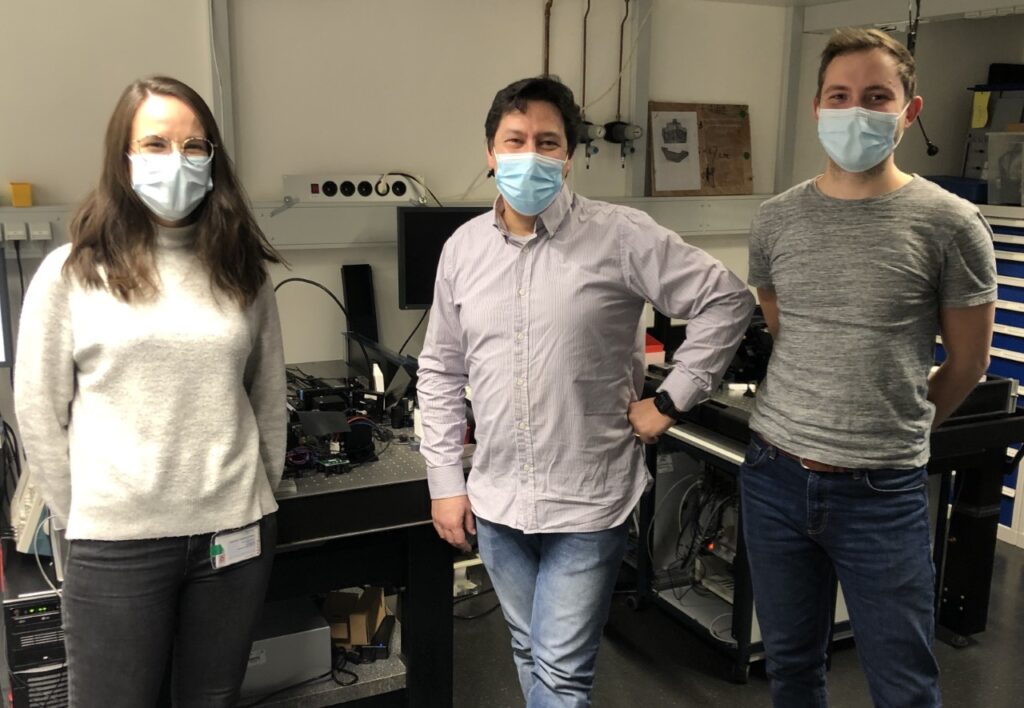

A recent work conducted by Brighter project researchers at Goethe University Frankfurt, Louise Breideband, Levin Hafa Francesco Pampaloni and colleagues, describes the development of an open-source bioprinter device based on a consumer-grade 3D light stereolithographic (SL) printer. This new SL bioprinter can produce complex constructs that preserve cell viability and recapitulate the physiology of tissues.

Researchers working on regenerative medicine and disease modelling have been betting, for the last years, on the use of 3D bioprinting methodologies to circumvent the gap between cell culture and human tissue, with applications that go from drug screening to organ transplantation. This technology is based on the combination of biomaterials (as scaffolds) and cells to produce functional complex tissues, by the accurate deposition of the material according to a computer-generated design. Nevertheless, the high cost of commercially available devices, ranging from $1,500 to $1 million, limits the use of 3D bioprinters in small and medium-sized laboratories with modest budgets.

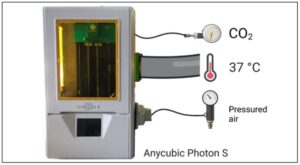

With the aim to enable and democratize the use of 3D bioprinting in basic and translational research, researchers led by Brighter partners from the Physical Biology Group at the Buchmann Institute for Molecular Life Sciences (BMLS), Goethe University Frankfurt in Germany, developed an open-source and low-cost device based on a consumer-grade commercially available low-cost and small footprint 3D stereolithographic (SL) printer. Detailed documentation of the modifications apported to the printer as well as a throughout performance analysis are available to the scientific community in an effort to spread out the use and application of this technique in different biomedical fields. The work has been submitted to Advanced Materials Technology and it is available on bioRxiv.

Using this customized device, photocrosslinkable hydrogels are selectively solidified in a layer-by-layer manner that additively builds up 3D structure. As the material deposition and crosslinking (using light) occur simultaneously, this approach increases the bioprinting speed. Additionally, the bioprinter was customized to print several objects at once (eight in this paper, but a 96 well-plate can also be integrated in the system).

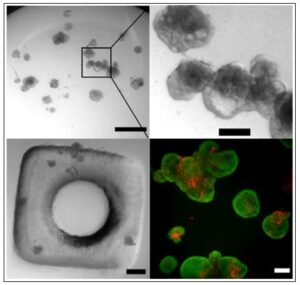

To fine tune the new device and set up the conditions, researchers produced 3D constructs consisting of patient-derived cholangiocarcinoma organoids (liver cancer) encapsulated in a gelatin methacrylate (GelMA)/polyethylene glycol diacrylate (PEGDA) hydrogel. By adjusting different parameters, they were able to mimic the specific tumour micro-environment and conclude that the bioprinted synthetic hydrogel provides a flexible and adequate replacement of animal-derived reconstituted extracellular matrix (as for example Matrigel, a murine-derived extracellular matrix extract routinely used for 3D cell culture). The organoids showed an average cell viability of 97% after bioprinting. Additionally, the authors could also confirm that 405 nm light caused little DNA damage and the unpolymerized hydrogel caused some oxidation but no inflammation.

In conclusion, authors show that this affordable consumer SL printer can be straightforwardly modified for bioprinting and most importantly, the constructs obtained show a high viability of patient-derived cells.

“We hope that our “do-it-yourself” SL bioprinter will pave the way for a widespread adoption of bioprinting in cell biology and translational research laboratories”.

Reference article: Bioprinting the Tumor Microenvironment with an Upgraded Consumer Stereolithographic 3D Printer. Louise Breideband, Kaja N. Wächtershäuser, Levin Hafa, Konstantin Wieland, Achilleas Frangakis, Ernst H. K. Stelzer, Francesco Pampaloni. bioRxiv