Brighter is a European Project that brings together different academic and industrial partners to develop a new 3D bioprinting technology able to produce human tissues at high speed and with high spatial resolution. This innovative technology is based on light-sheet lithography and an original top-down approach.

Pontus Stenström is a physician and senior specialist at MYCRONIC, a Swedish high-tech company that has been active in the electronics industry for more than 30 years. In 2000 Pontus joined the company where one of his main tasks has been to develop electronics to control the laser light for the pattern generators. Read the interview below and enjoy!

Can you describe yourself in a couple of lines?

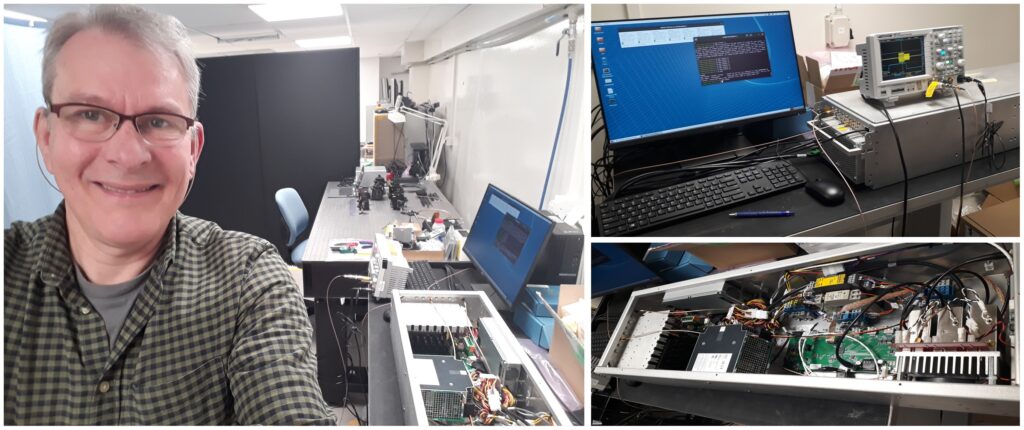

I’m Pontus Stenström and I have a background from the Stockholm University physics department where I was a part of developing instrumentation for various physics experiments, in my case acquisition electronics for a tomography (SPECT) camera. I’ve now been at Mycronic since 2000, mainly developing electronics to control the laser light (modulation and deflection) for our pattern generators.

What is your role/position within Brighter?

My part in Brighter has been to design/build the “AOM/AOD rack” which is the rack controlling the laser Modulation and Deflection using Acousto Optical elements. Also some adaptations to fit better into the Brighter setup. The AO technology is about 100 years old and consist of creating sound wave in a crystal to diffract light as the sound generates a kind of grating in the device. The frequencies involved are hundreds of MHz.

Could you tell us a little bit about the concrete work you’re involved in inside Brighter project?

Most of the AOM/AOD rack has direct counterparts in our pattern generators, so a small number of changes were required to adapt to Brighter. For example I made some scripts to ease the specific setup needed here. The optics, laser, alignment etc. are done by other people here.

What are the expected results?

The result is from our (Mycronic) part to deliver a system that can scan (or sweep) a laser beam while modulating it on and off, my parts are all the electronics and cables from the controlling computer up to the AOM/AOD devices.

What is the expected impact of the work you’re doing?

The SW we provide will take an bitmap image and produce the required actions from the AOM/AOD to create (by sweeping in time) lines – similar to an CRT. The vertical movement of the line is handled by GUF I believe.

How do you feel about being a part of this European Project?

It feels exciting, partly because it is so multidisciplinary and involves so many technologies, so I certainly risk to learn something new!