Source: Goethe-Universität Frankfurt am Main

EU Project BRIGHTER sets its sights on 3D bioprinting systems with light sheet lithography.

FRANKFURT. The production of artificial organs is a hot research topic. In the near future, artificial organs will compensate for the lack of organ donations and replace animal experiments. Although there are already promising experiments with 3D printers that use a «bio-ink» containing living cells, a functional organ has never been created in this way. A European consortium coordinated by Dr Elena Martinez (IBEC, Barcelona, Spain) and involving the Goethe University Frankfurt is now breaking new ground. The consortium is developing a lithography method that relies on light sheet illumination and on special photosensitive hydrogels that are mixed with living cells.

Bio-printing systems that build up structures layer by layer (bottom-up approach) have considerable disadvantages. On the one hand, the printing process takes far too long, so that the survival chances of the cells in the bio-ink and in the polymerised layers considerably decrease. Furthermore, the extrusion pressure leads to a considerable cell death rate, especially for stem cells. In addition, the resolution of the method, around 300 micrometers, is far too low to reproduce the delicate structures of natural tissue. Finally, it is particularly difficult to integrate complex hollow structures, e.g. blood vessels, into the cell tissue.

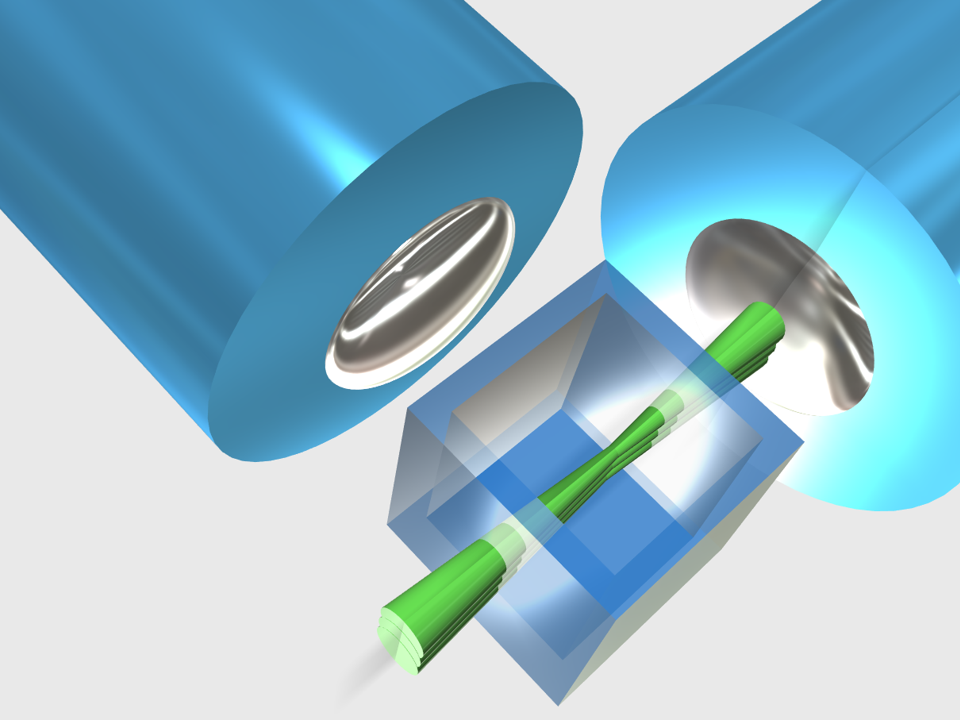

«With our project, we want to go the other way round by developing a top-down lithography method,» explains Dr. Francesco Pampaloni from the Buchmann Institute for Molecular Life Sciences (BMLS) at Goethe University. The process works in a similar way to lithography in semiconductor technology. Instead of the semiconductor and the photosensitive layer, which is illuminated by a mask, a hydrogel with photosensitive molecules is used. This is exposed to a thin laser light sheet using the technique invented by Prof. Ernst Stelzer for light sheet microscopy. This leads to the formation of branched chain structures (polymers) that serve as a matrix for colonisation by living cells. The remaining, still liquid hydrogel is washed out.

«This method will enable us to adjust the spatial structure and the stiffness with an unprecedented resolution so that we can create the same heterogeneous microstructures that cells find in natural tissues,» explains Pampaloni. Pampaloni expects that completely new possibilities will emerge for the bio-fabrication of complex tissues and their anatomical microstructures. In addition, the specific properties of the matrix can be used to introduce stem cells into well-defined compartments or to enable the formation of vessels. Further advantages over conventional 3D printing systems are high speed and cost-effective production.

BRIGHTER stands for «Bioprinting by light sheet lithography: engineering complex tissues with high resolution at high speed». Starting in July 2019, the project will be funded for three years as part of the European Union’s renowned and highly selective «Future and Emerging Technologies» (FET) Open Horizon 2020 Programme. BRIGHTER will be financed with a total of € 3,450,000, of which € 700,000 will go to a team led by Dr. Pampaloni in Prof. Stelzer’s Physical Biology Group in the Biosciences Department of the Goethe University. Further partners are the IBEC (Barcelona, Spain, coordination), Technion (Haifa, Israel) and the companies Cellendes (Reutlingen, Germany) and Mycronic (Täby, Sweden).

An image may be downloaded here: http://www.uni-frankfurt.de/78299401

Credit: F. Pampaloni, BRIGHTER, 2019

Caption: Light sheet bio-printing. A hydrogel composed of living cells and photosensitive molecules is deposited in a special cuvette. A thin laser light sheet illuminates the gel following a programmed pattern (green beam). This leads to the formation of 3D micro-structures that reproduce the tissue architecture and function. The remaining, still liquid hydrogel is washed out after the printing process.

Further information: Dr Francesco Pampaloni, Physical Biology, Faculty of Biological Sciences, Riedberg Campus, Phone: (069) 798-42544, fpampalo@bio.uni-frankfurt.de, https://www.physikalischebiologie.de/people/francesco-pampaloni

Current news about science, teaching, and society can be found on GOETHE-UNI online (www.aktuelles.uni-frankfurt.de)

Goethe University is a research-oriented university in the European financial centre Frankfurt am Main. The university was founded in 1914 through private funding, primarily from Jewish sponsors, and has since produced pioneering achievements in the areas of social sciences, sociology and economics, medicine, quantum physics, brain research, and labour law. It gained a unique level of autonomy on 1 January 2008 by returning to its historic roots as a «foundation university». Today, it is one of the three largest universities in Germany. Together with the Technical University of Darmstadt and the University of Mainz, it is a partner in the inter-state strategic Rhine-Main University Alliance. Internet: www.uni-frankfurt.de

Publisher: The President of Goethe University Editor: Dr. Anne Hardy, Science Editor, PR & Communication Department, Theodor-W.-Adorno-Platz 1, 60323 Frankfurt am Main, Tel: -49 (0) 69 798-13035, Fax: +49 (0) 69 798-763 12531, hardy@pvw.uni-frankfurt.de.

Wissenschaftliche Ansprechpartner:

Dr Francesco Pampaloni, Physical Biology, Faculty of Biological Sciences, Riedberg Campus, Phone: (069) 798-42544, fpampalo@bio.uni-frankfurt.de, https://www.physikalischebiologie.de/people/francesco-pampaloni