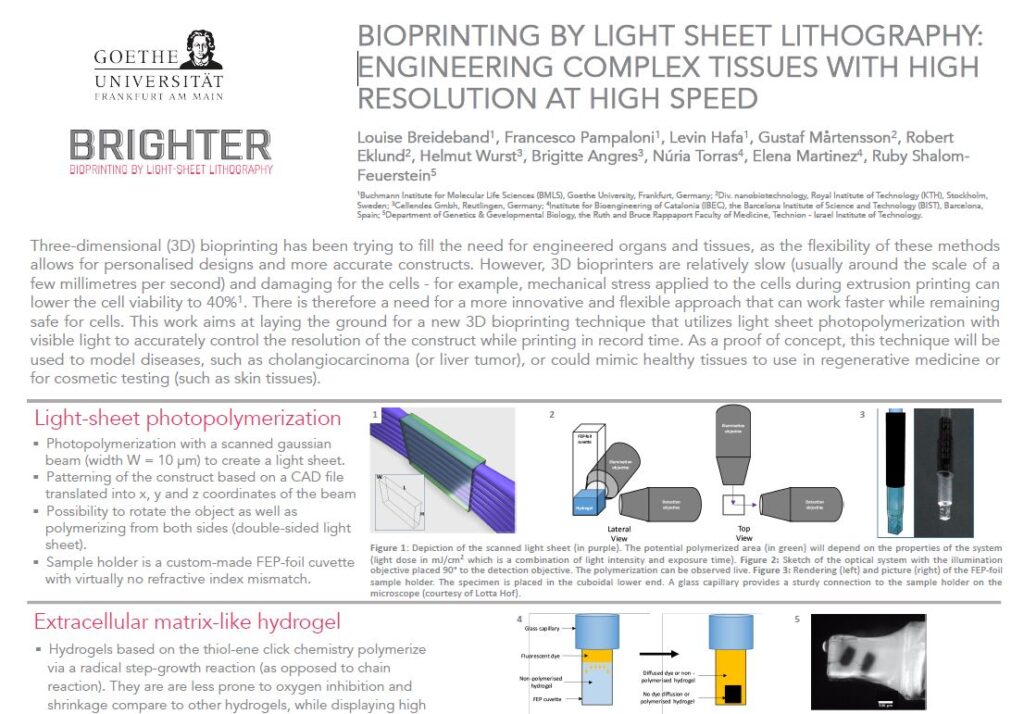

Brighter is a European Project that brings together different academic and industrial partners to develop a new 3D bioprinting technology able to produce human tissues at high speed and with high spatial resolution. This innovative technology is based on light-sheet lithography and an original top-down approach.

Louise Breideband is a PhD student in the frame of Brighter Project at the Physical Biology laboratory in the Buchmann Institute for Molecular Life Sciences, Goethe University Frankfurt. After a master’s degree in food production and a couple of years doing scientific communication, she decided to come back to the lab! She completed a master’s degree in physical biology of cells and cell interactions, and now she is performing a PhD and contributing to Brighter project in the development of a 3D bioprinter using light sheet photopolymerization. Get to know more about Louise in this interview!

Can you describe yourself in a couple of lines?

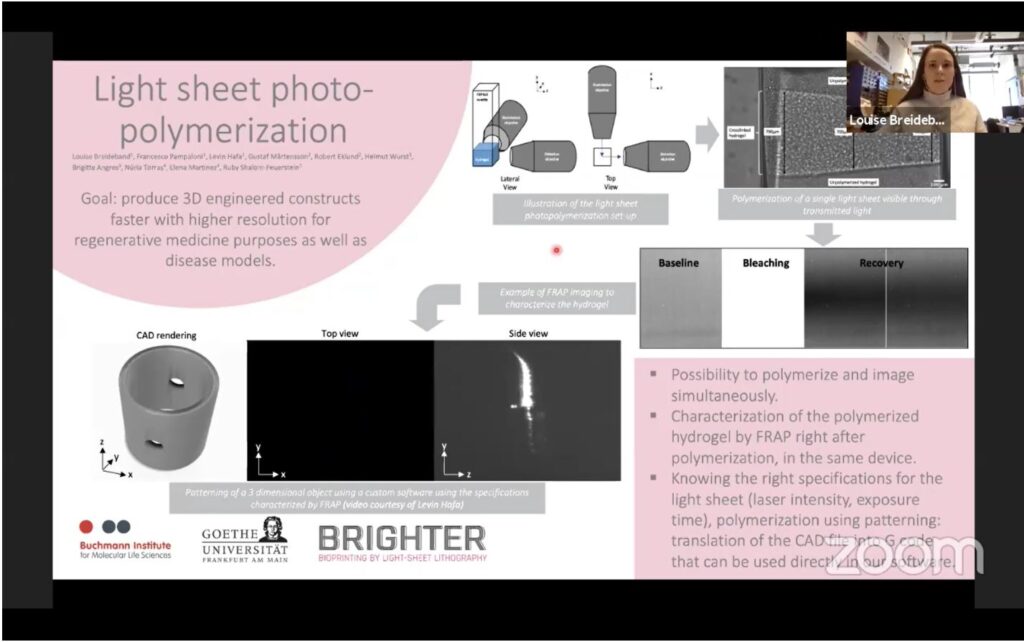

My name is Louise Breideband, I am a PhD student in the Physical Biology lab in the BMLS, Goethe University Frankfurt. Our lab is specialized in microscopy, especially light-sheet microscopy and high-resolution imaging. I am originally French and graduated with a master’s degree in food production from the university of AgroParisTech (Paris, France). I worked for a couple of years in Australia and Germany as a scientific communication expert, but I soon realized that I was missing hands-on work in a laboratory. I completed a master’s degree in physical biology of cells and cell interactions in the Goethe University Frankfurt before joining Professor Stelzer’s lab for my master thesis and PhD thesis. Under Dr. Pampaloni’s supervision, I am working closely with Levin Hafa on developing a 3D bioprinter using light sheet photopolymerization. Additionally, I am assisting on a project developing a 3D model of bone marrow using spheroids that will be exposed to microgravity and sent to the international space station in 2022.

What is your role/position within Brighter?

I am at the interface between the different participants in the project, testing various hydrogel compositions delivered by Cellendes and encapsulating fibroblasts following protocols developed by IBEC and Technion, printed on the 3D bioprinter prototype built by us in cooperation with Mycronic.

Could you tell us a little bit about the concrete work you’re involved in inside Brighter project?

I am confirming that results established by IBEC, Technion or Cellendes still apply when using our innovative 3D bioprinter. For example, my first task was to determine how the hydrogel was polymerizing when initiated with a light-sheet, which I demonstrated using fluorescent dye diffusion and FRAP (fluorescent recovery after photobleaching). Then, I tested the cell viability of fibroblasts printed in various hydrogel compositions and imaged the cells in live under a light sheet microscope for 7 to 9 days. Finally, using the patterning developed by Levin Hafa and Mycronic, we printed the cells in a more intricate design, showcasing the full capacity of the prototype. The next step would be to co-culture the fibroblasts and the keratinocytes in the printed constructs.

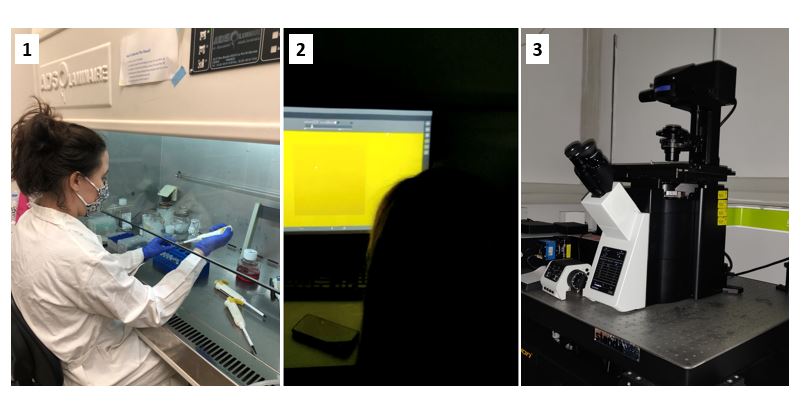

1- Mixing the hydrogel and the cells before printing.

2- Looking at cells under the microscope. Fibroblasts were dyed with a live fluorescent dye so that we can observe the cells after 3D bioprinting.

What are the expected results?

We expect the cells to grow, multiply and express markers when 3D bioprinted as fibroblasts would do in vitro. Early results are very encouraging in this regard. Eventually, we would like to develop a functional 3D bioprinter that is suitable to encapsulate cells in high definition while mimicking the in vitro environment.

What is the expected impact of the work you’re doing?

At Goethe University Frankfurt, we are at the crossroad of all our colleagues in the partner institutions. We closely work with them to make sure that all the intricate parts of this project come together. Currently, we have the only prototype in the project which makes us responsible for delivering results using this prototype, as well as further developing it and sharing our observations with our partners, building a feedback loop that fully exploits this collaboration.

How do you feel about being a part of this European Project?

As a product of Europe myself, I feel very proud to be involved in this journey. I love working on a multi-disciplinary project which allowed me to professionally grow in the last two years. Unfortunately, because of the pandemic, it has been very difficult to physically interact and visit each other, which is a real shame. However, online communication flourished and thanks to video calls, we are still able to see each other and reach out on a regular basis.